StormVoid supports concrete for below-grade construction on expansive soils. Its durable design creates permanent void space and uniformly distributes loads, even in wet conditions or bad weather.

Non-Degradable

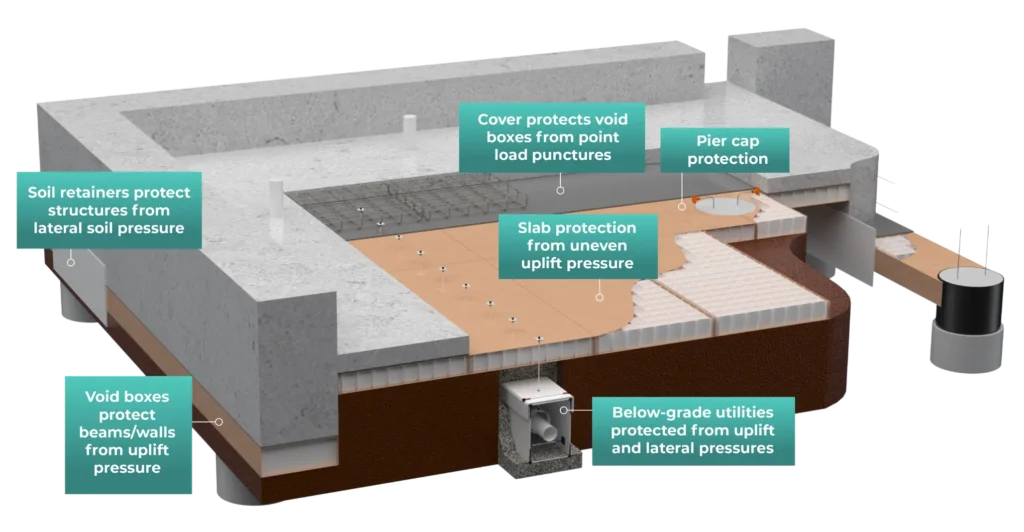

System and Components

StormVoid’s performance is based on its non-degradable interior components, unlike paper void products, which degrade with moisture. While both materials maintain a void space between slab and soil to prevent uplift damage from expansive soils, these waterproof void forms can be installed in wet conditions. System components include void forms, cover boards, vapor barriers, and backfill retainers.

Why Specify StormVoid

Have Greater Confidence

Strong enough to withstand steel and wet concrete placement but weak enough to collapse as the soil expands.

Ensure Longevity

Long-term protection for concrete slabs, beams, and piers from lateral and upward pressure.

Stay on Schedule

StormVoid can be placed in wet weather, even submerged, to ensure you stay on schedule, no matter the site conditions.

Go Easy on the Crew

A complete, assembled, lightweight unit, StormVoid handles and installs easily. No special skills or tools required.

System Components

Slabs, Beams & Piers

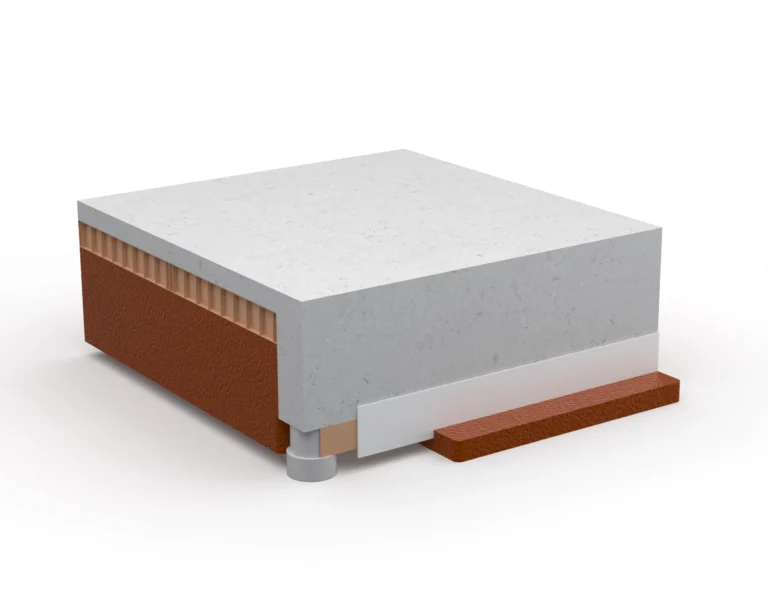

StormVoid Slab

Placed under structural slabs from 6″ to 60″ thick, StormVoid Slab’s wax coated carton wrap degrades with persistent moisture leaving the copolymer polypropylene plastic cellular structure for soil in which to migrate.

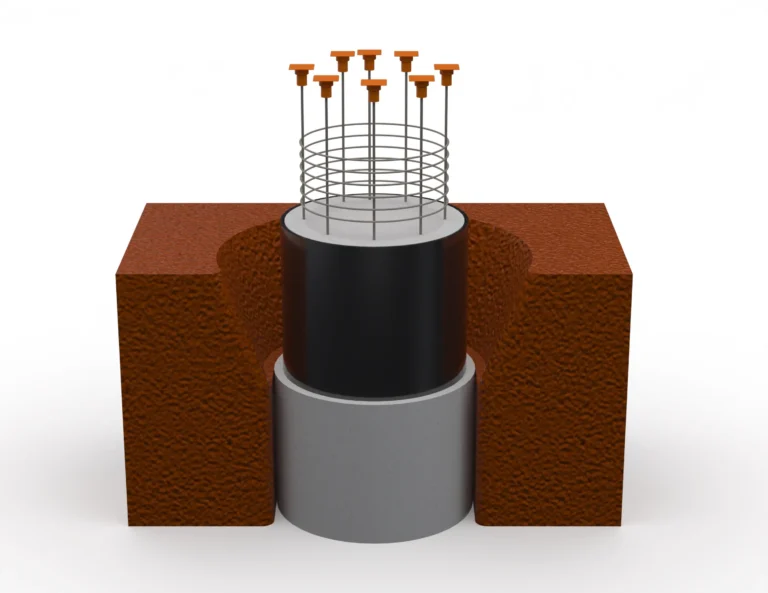

StormVoid Pier

Made from StormVoid Slab components StormVoid Pier is a pre-manufactured, non-field-cut, sealed corrugated carton void form that fits the pier diameter.

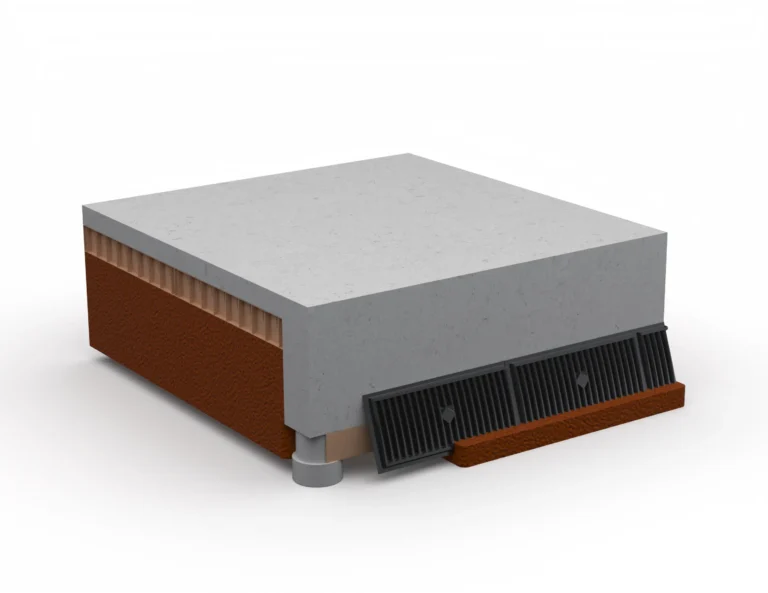

StormVoid Beam

Placed under vertical walls and beams, typically 2′ to 10′ tall, StormVoid Beam’s cell structure and PPC materials support the weight of wet concrete until curing is complete.

Soil Retainers & Protectors

BackFill Retainer

Prevent backfill soil from displacing the void space under grade beams and slab edges. The polypropylene copolymer plastic BackFill Retainer is available in a wide range of sizes and strengths.

Cover Boards

Cover Boards provide protection against point-load punctures which could allow liquid concrete to inadvertently seep into the void space.

SureCover Boards™ come in a range of weights for light, medium, moderate and standard protection of the void form surface.

StormCover Board™ is 5.00 mm weatherproof protection for underlying void forms.

Plywood may be used in extreme circumstances and is available upon request.

SureRetainer

SureRetainers are lightweight HDPE plastic and are ideal for void spaces less than 16″ tall.

SureTops

By forming and containing the upper 2-foot portion of poured-in-place concrete piers, SureTops create a smooth edge to ensure uplift pressure does not damage the pier.

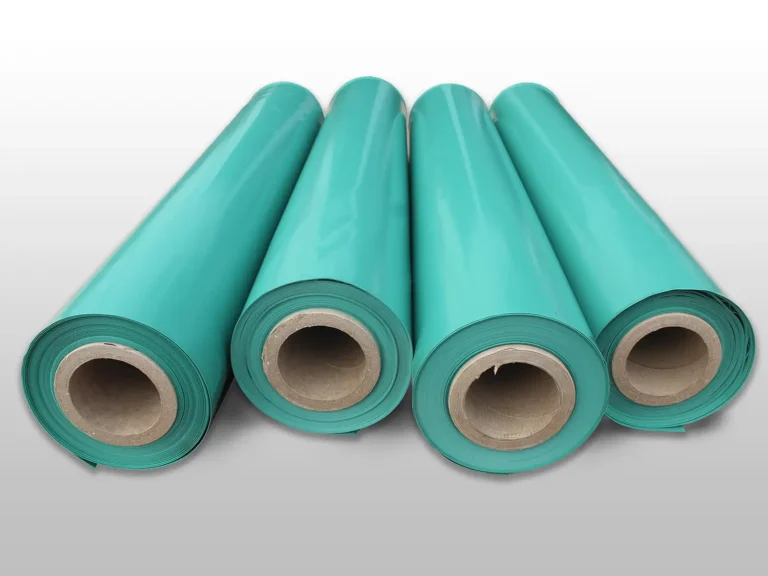

Vapor Barriers

Plastic sheets in a variety of grades and thicknesses that are placed between the carton form system and the bottom of the concrete to prevent moisture from coming up into the structure.

Documentation

-

- StormVoid Product Overview (VIDEO)

- 03 1001 Product Spec Sheet (PDF)

- StormVoid Product Info Sheets (PDF)

- BackFill Retainer Product Info Sheet (PDF)

- Cover Boards Product Info Sheet (PDF)

- StormVoid Beam (PDF)

- StormVoid DropPanel (PDF)

- StormVoid Pier (PDF)

- StormVoid Slab (PDF)

- SureRetainer Product Info Sheet (PDF)

Bringing It All Together

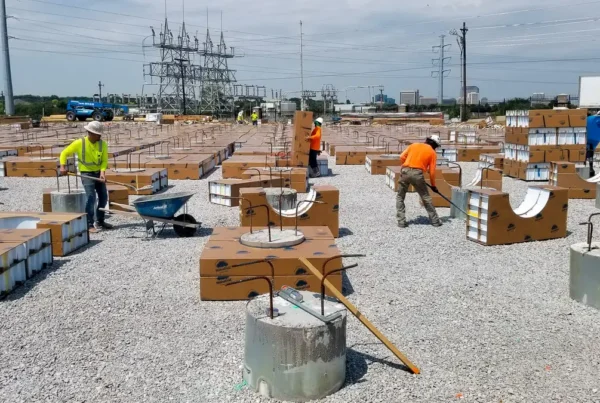

Recent projects showing how different components of the StormVoid System can work together for various real-world applications.