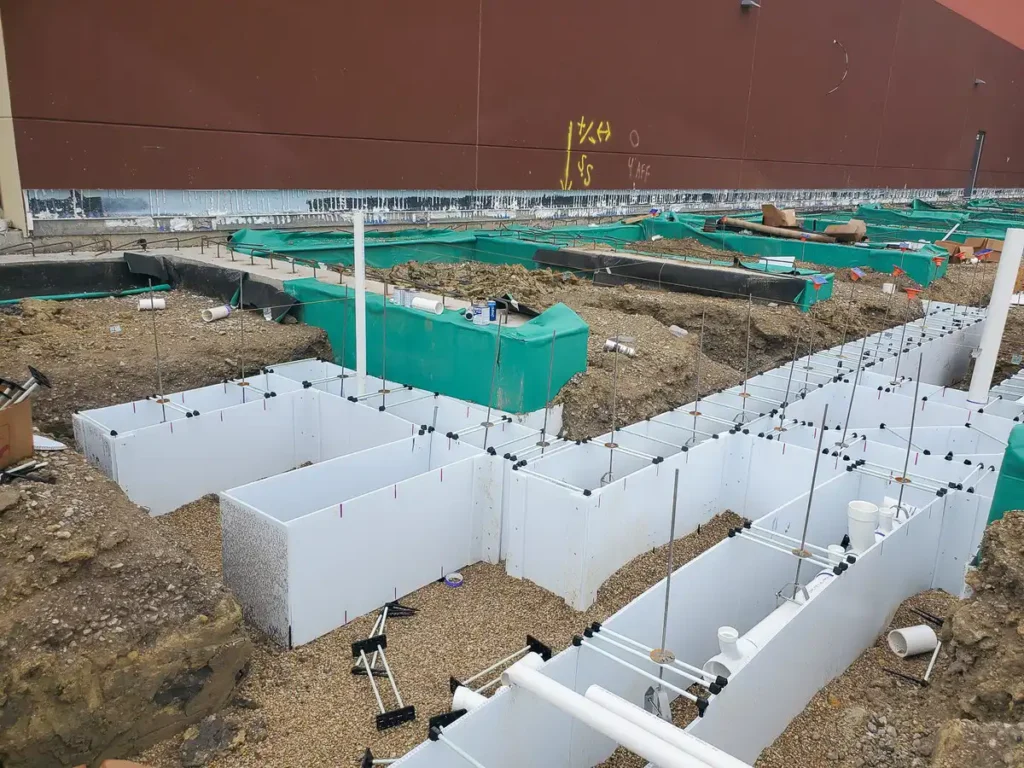

PlumbingVoid protects below-grade plumbing and conduit from expansive and corrosive soils. Its durable design creates permanent void space and uniformly distributes loads, even on challenging construction sites.

PlumbingVoid

System and Components

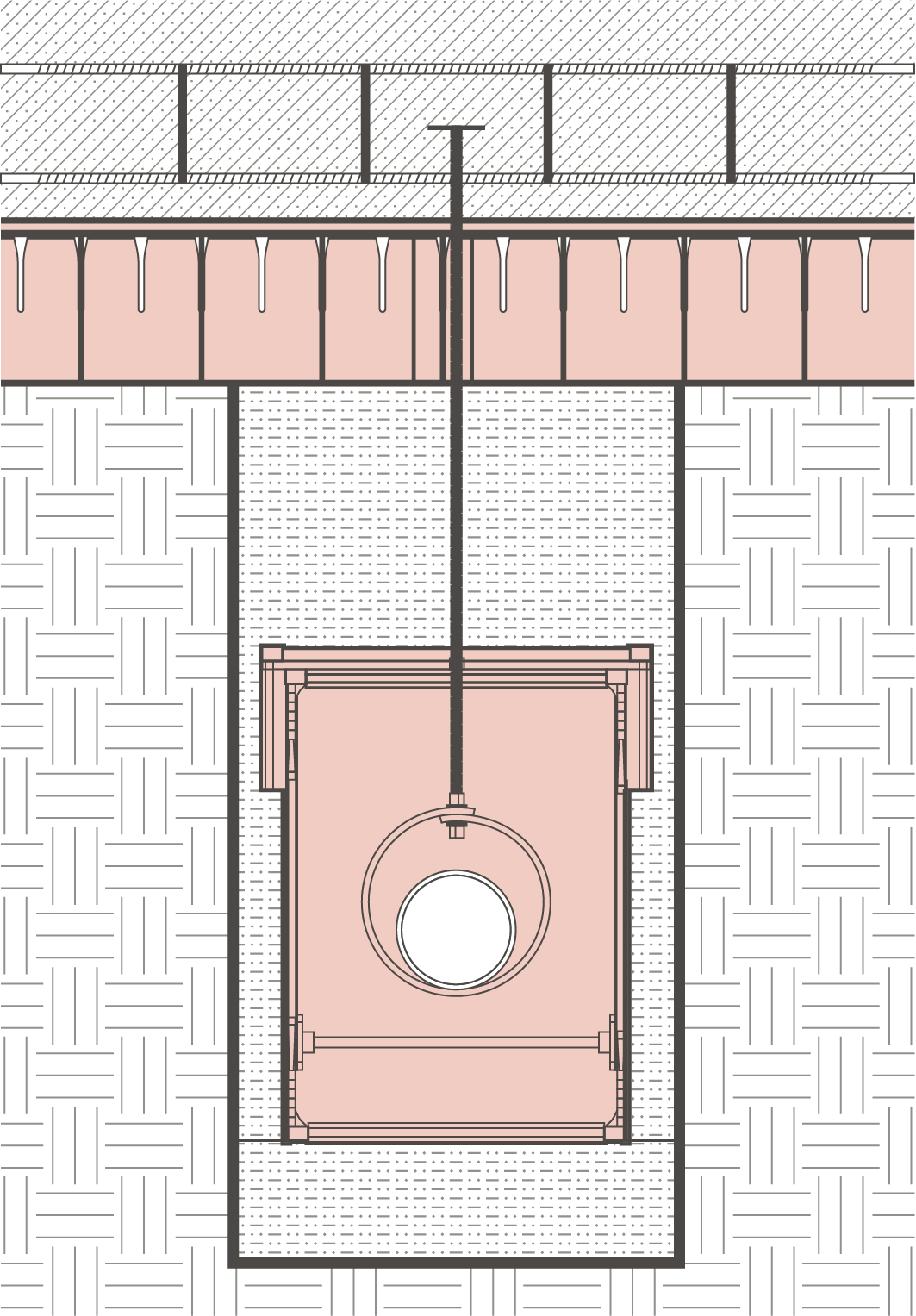

When uplifting soil pressure occurs beneath the structural slab, the open space of the PlumbingVoid system is designed to receive the infill of vertical expansion from the underlying soils. By patented design, the pressure is exclusively applied to the system and not the pipes. PlumbingVoid moves separately and independently from the lateral pipes.

Why Specify PlumbingVoid

Eliminate Costly Damage

Creates a permanent void space between newly placed plumbing lines and surrounding soil to eliminate damage caused by expansive soil.

Easy to Install

Assembles quickly using lightweight and corrosion-proof plastic with pre-scored corners and marks for plumbing lines. No special tools required.

Simple Onsite Adjustments

Adjusts easily to modify the pipe slope. Additional assemblies can be added to increase resistance to vertical and lateral pressures.

Faster Inspections

Inspection-friendly design allows the top caps to remain off until inspection is complete.

System Components

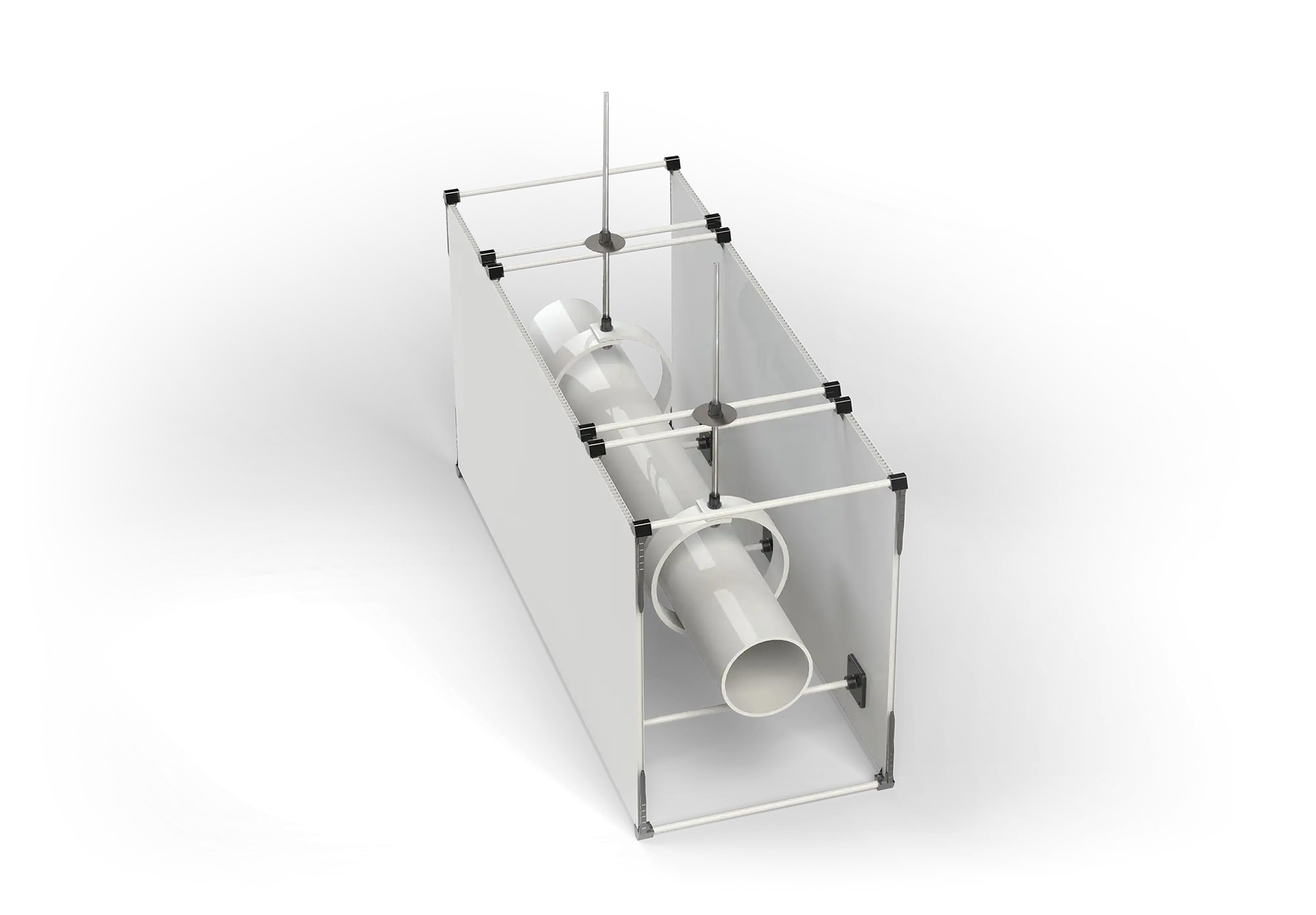

Void Space & Lateral Support Assemblies

The PlumbingVoid side panels, end caps, and top caps are constructed from channeled polypropylene, providing rigid support in humid conditions, inclement weather, and even when submerged.

Standard support spacing may be reduced to add more strength for deep trench applications.

For additional flexural strength, optional stiffening rods or additional crossbar assemblies may be used above or below the pipe.

Pipe Support Assembly

The Super Hanger™ includes a fiberglass threaded rod and PVC pipe hanger to meet the requirements of a non-corroding system. In combination with VoidForm’s proprietary washer and crossbars, the assembly is a versatile solution that accommodates a variety of pipe sizes and weights.

When soil pressure is applied, the washer is designed to flex so that the system moves independently of the hanger assembly, keeping pipes protected from bending or breaking.

PlumbingVoid Detail

Construction systems working together

VoidForm’s products enable engineers to design a complete solution to mitigate risk.

- Washer

- Side panels, end/top caps

- Spacer/crossbar assemblies

- Connector/crossbar assemblies

- Optional stacking pins

- Optional stiffening rods

- Fiberglass threaded rod

- Hex flange nut

- Threaded rod coupler

- PVC pipe hanger

Documentation

- PlumbingVoid Product Overview (VIDEO)

- PlumbingVoid Product Info Sheet (PDF)

- PlumbingVoid Technical Notes (PDF)

- 22 1000 Product Spec Sheet (PDF)

Bring It All Together

A few recent PlumbingVoid projects, which incorporated existing components.