Void forms are critical components used below and around concrete structures that are built on sites with expansive and otherwise damaging soil conditions. These forms prevent the destructive effects of expansive, collapsible, corrosive, and seismic soils by isolating concrete slabs, beams, walls, and piers from direct soil contact and immense and damaging pressure potential.

There are several types of void forms used across the construction industry today, including carton forms, plastic void forms, and EPS foam options. Each void form type and material varies in design, cost, durability, and performance, to be specified depending on project requirements.

The following is a breakdown of each of the most common types of void forms, including materials.

What Is a Void Form?

Void forms create a permanent void space between damaging soils and concrete structures. Damaging soil types include expansive, collapsible, seismic, or corrosive soils, with expansive soils being the most prevalent and destructive in North America.

Sometimes referred to as sacrificial formwork or void boxes, void forms are installed below and around concrete slabs, beams, walls, and piers as isolation against the potential pressure exerted by the surrounding shrinking and swelling soil. With slab-on-void, the soil moves into the purpose-built void space instead of directly into the above-grade structures, thereby preventing damage.

While void forms are primarily used to protect against highly expansive soils, they also play a crucial role in mitigating the related impacts of frost heave in colder climates. Additionally, contractors frequently use void boxes to reduce excavation costs and minimize concrete usage.

Types of Void Forms: Degradable, Non-Degradable, and Non-Collapsible

Void forms fall into two main category types: degradable and non-degradable. A tertiary type, non-collapsible, is rarely required and, if so, only in specific circumstances.

Degradable Void Forms

Also called biodegradable, degradable void forms are made from mold paper or corrugated carton materials that break down and/or collapse when exposed to sufficient environmental moisture to create the specified void space.

Carton forms are lightweight, simple to install, and generally more cost-effective than other types. Because paper-based void forms are built to degrade with exposure to moisture, they must be kept dry before concrete is poured.

Non-Degradable Void Forms

Non-degradable void forms are typically made from collapsable or crushable materials that resist moisture-related degradation, like plastic and synthetic polystyrene (expanded polystyrene foam, also known as EPS foam). Unlike degradable versions, non-degradable voids are water resistant, which means they can be installed on wet job sites or in unpredictable or inclement weather conditions.

No matter the site conditions, the forms do not degrade when wet. Instead, plastic void forms are robust enough to support concrete structures during pouring but weak enough to crumple under the pressure of expansive soil. It should be noted that EPS foam voids technically do not collapse like other plastic designs. Instead, EPS foam compresses with the upward swell from expansive soil.

Non-degradable void forms are more costly than carton types simply due to the nature of the material. However, significant trickle-down savings are achieved elsewhere. They do not need to be replaced if damaged by wet weather. They ensure construction stays on schedule, regardless of weather or job site conditions.

Non-Collapsible Void Forms

A much less common class of void forms are non-degradable and non-collapsible. Typically made from materials like rigid plastic, wood, concrete, or metal, these void forms are designed to remain permanently.

Unlike collapsible void forms, which are explicitly made to deteriorate, compress, or crush over time to create space for soil movement, non-collapsible void forms remain intact and serve as a barrier or support beneath foundations.

Image credit: Wikipedia

Common Types of Void Form by Material Type

Void forms come in various materials, each suited to different applications, weather conditions, budgets, and, at times, contractor preferences. Below are the most commonly used materials for void forms:

Carton Forms

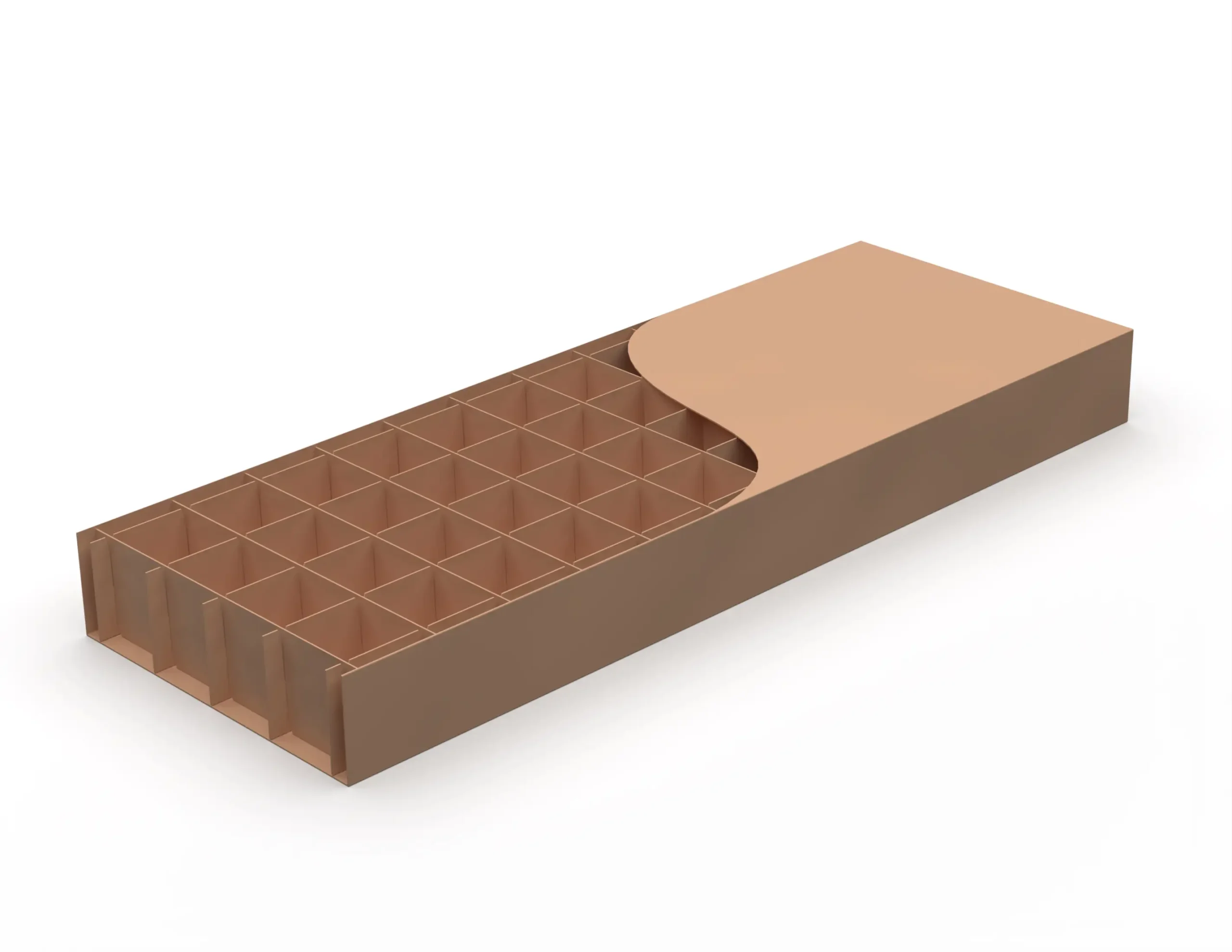

Made from corrugated or molded paper, carton forms come in various designs and internal support structures depending on strength requirements and manufacturer. Carton forms are both degradable and collapsible void forms. They are designed to temporarily support concrete loads before breaking down to create a permanent void space.

For example, VoidForm’s SureVoid® system consists of corrugated paper with an internal support structure designed to withstand varying heights and weights of concrete placement. SureVoid has a paraffin wax coating that helps prevent premature degradation, ensuring each form maintains integrity in dry conditions until the concrete hardens. While materials and designs may vary, all carton voids are built to hold their shape through installation and initial curing stages before gradually breaking down in the face of environmental moisture.

Carton forms are available in various shapes, densities, sizes, and strengths, making them adaptable for various applications.

Plastic Forms

Plastic void forms, or void boxes, are made from water-resistant or water-proof materials. For example, VoidForm’s StormVoid® System has a waterproof interior made from copolymer polypropylene (PPC) and a degradable, moisture-resistant cardboard exterior. Plastic voids, like StormVoid, are deployed during the rainy season, for unexpected weather forecasts, and on wet and muddy job sites.

Plastic forms are non-degradable voids but are designed to be flexible or collapsible under the pressures exerted by expansive soils. At first glance, plastic forms are more expensive because of the cost of plastic compared with paper. However, plastic voids are frequently specified as a cost-saving measure. They ensure construction can continue even in inclement weather conditions. This helps reduce site downtime, concrete delays, and product replacement costs should rain come into the forecast.

Available in any number of sizes, strengths, and shapes, they may be installed anywhere that paper-based void forms for concrete slabs are used.

EPS Foam

Expanded polystyrene (EPS) foam voids (sometimes called void foam) are non-degradable, water-resistant void forms used in below-grade applications where expansive soils are a concern. They are also used as lightweight alternatives to sand or stone fill.

EPS voids are produced by heating, expanding, and fusing polystyrene beads, creating a solid yet air-filled structure within closed cells. Unlike true collapsible void forms, EPS foam is compressible rather than fully collapsible. This means it resists the pressure of expansive clay rather than allowing soil movement into an open void space.

Several EPS foam designs are used today, with a high degree of variability between manufacturers regarding ease of installation and required site clean-up. Two of the most common types of EPS are a honeycomb-like structure and a tabletop design with vertical supports. Their compressive strength varies based on density and grade. Although EPS foam voids remain widely used in Canada, they are much less common in the U.S. due to environmental concerns and the emergence of other cost-effective alternatives.

In the Face of Damaging Soil, the Type of Void Form Matters

Choosing the right void form is essential for protecting concrete structures from expansive, collapsible, or frost-prone soils. Degradable void forms provide a cost-effective solution for dry conditions, while non-degradable options offer durability in unpredictable weather.

By selecting the right type of void form and material type, engineers and contractors can not only prevent foundation damage but also keep products on budget and on time.

FAQs

What are cardboard concrete forms?

There can be some confusion between carton void forms and cardboard concrete forms (or concrete foundation forms). Void forms prevent soil-related foundation damage by creating an engineered gap, while cardboard concrete forms shape structural elements and do not collapse after curing.

Concrete foundation forms are used during traditional concrete formwork. Void forms are used to prevent structural damage to concrete structures from expansive, corrosive, seismic, or collapsible soils.

Can void forms get wet?

It depends on the material. Plastic-based void forms are water-resistant and can withstand wet conditions without degrading. However, paper-based void forms are designed to break down when exposed to soil moisture, so they must remain dry until after the concrete is placed and curing has begun.

Premature water exposure can weaken their structure, compromising their ability to create a proper void space. For projects facing rain, standing water, or unpredictable site conditions, a waterproof alternative like StormVoid® is the better choice.

How long does a void form last?

VoidForm products, including SureVoid® and StormVoid®, are engineered to protect structures from challenging soil conditions for their functional lifespan. But, if the question refers to how long the form remains intact under concrete before breaking down to create the void space, the answer depends on the material and site conditions.

Degradable void forms (like SureVoid) are intentionally designed to degrade. Made from corrugated paper, they gradually degrade after installation as they absorb soil moisture, creating a permanent void space.

Non-degradable void forms (like StormVoid) are made from moisture-resistant materials like plastic. These remain intact through installation and withstand wet conditions but will collapse under soil pressure when needed.

How much void space is required?

The required void space is determined through a geotechnical site assessment to measure the shrink and swell potential of the landscape and specific soil makeup. A geotechnical engineer will assess the expansive potential and specify the required void space (for example, 4″) in and around concrete to mitigate the risk of damage.

With a geotechnical assessment complete, a structural engineer, and/or in cooperation with the geotechnical engineer, will detail mitigation strategies that may include void forms.