Find answers to common questions below. If you need additional assistance, contact us, and we’ll do our best to help you.

What does VoidForm do?

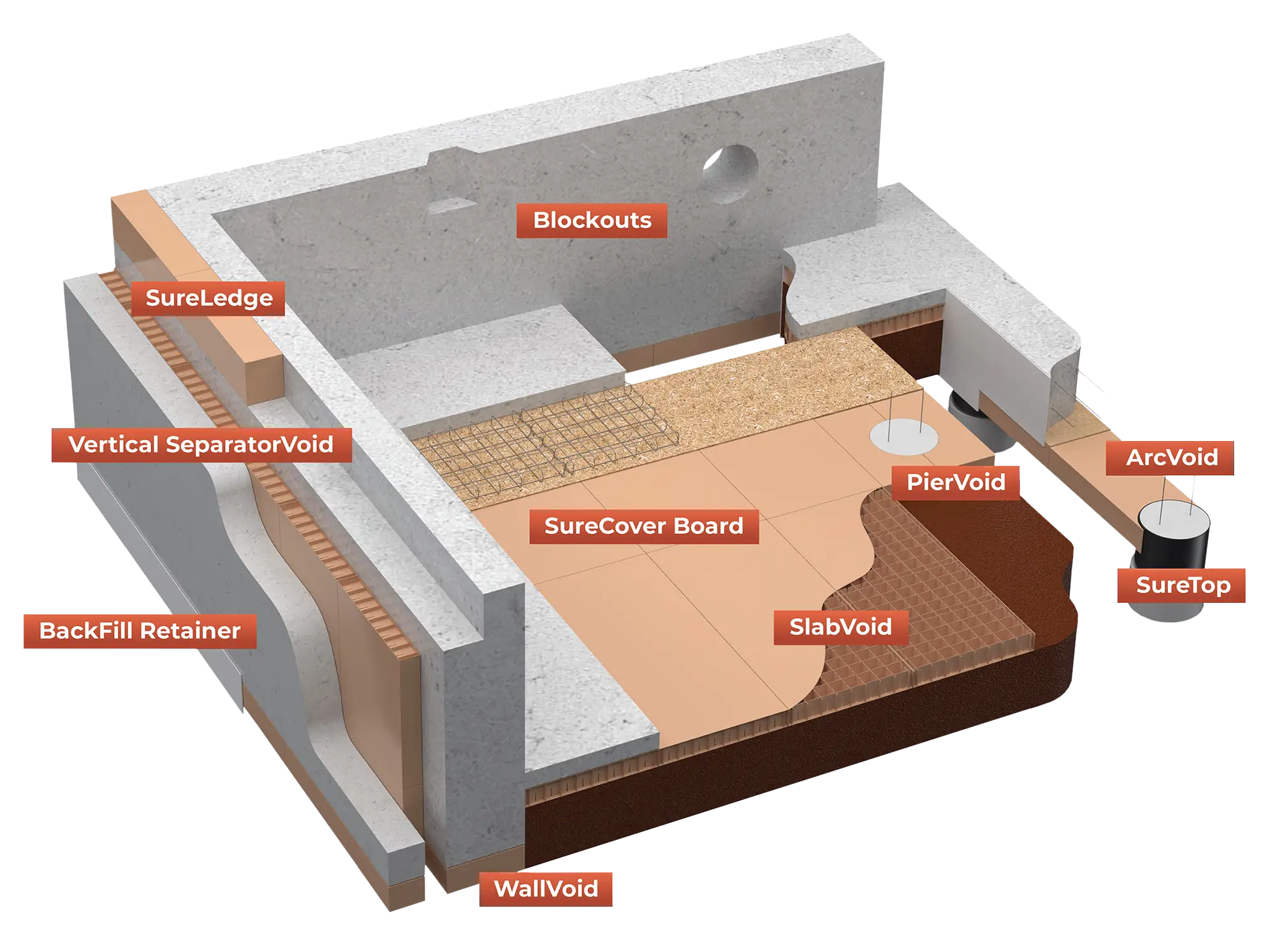

We design and manufacture products that protect concrete structures and underground utilities from expansive, collapsible, seismic, and corrosive soil damage. Our products help protect a wide range of concrete structures, including slabs, piers, and beams. In addition, we create easy-to-install and easy-to-remove custom blockouts that form unique reliefs in concrete work where problematic lumber or foam has traditionally been used.

What is the purpose of a void form?

Void forms prevent damaging soils from coming in contact with concrete structures. Damaging soils can include any expansive, collapsible, seismic, or corrosive soil condition. Expansive soil is prevalent in the U.S. and Canada. It causes concrete foundations to crack or heave, transferring forces to walls and ceilings that can cause additional damage.

How do void forms work?

Void forms create a space between the concrete structure and the surrounding soil. When placed under slabs or beams, particularly around drilled piers, the air pocket space created by the void form allows the soil to expand or heave without applying pressure or contacting the concrete structure. This prevents long-term damage.

Void forms, whether made from corrugated paper or plastic. They are strong enough to support concrete during the pouring and initial curing process yet will yield under additional pressure from soil, making them valuable in a wide variety of construction applications.

Are plastic and paper void products available in the same shapes and sizes?

For the most part, yes! The majority of our products were originally based on corrugated paper materials. However, we have designed standard, plastic StormVoid equivalents for most wall, beam, and pier applications. Custom products are also available.

Are all void forms the same strength?

No. The strength of every void product we manufacture is based on the height of the concrete on the project and several other variables our clients provide during the estimating process. VoidForm then configures the support network for each product application based on the various material types and strengths that are available.

Can I buy void products online or in a retail location?

Our products are available directly through VoidForm in most areas, or through established dealers and distributors. Due to the variability of the Potential Vertical Rise (PVR) of the soil for each project, as indicated in the Geotechnical report, the height of the concrete, and several other factors, VoidForm designs the void form configuration for each application to ensure the best possible outcome.

Can paper-based void forms get wet?

No! Corrugated paper void forms are designed to deteriorate through moisture absorption and should remain dry until the concrete is placed and curing begins. The soil moisture will trigger the degradation process.

If the construction site is facing wet conditions and/or inclement weather. StormVoid is an excellent alternative! Its flexible plastic interior supports are impervious to moisture and will function properly in wet conditions, even in standing water.

What happens if the paper void products are exposed to rain, sleet, snow, or groundwater before installation?

Because moisture causes degradation by design, corrugated paper void forms may not be sufficient to support the intended concrete load. DO NOT install corrugated paper products that have been subjected to moisture prior to the concrete placement.

If you’re concerned about inclement weather or ground moisture, ask your product advisor about switching your order to StormVoid.

Can I install paper void products that were wet, but now are dry?

No! The internal cell structure has likely been compromised, and the product’s strength may be unpredictable. Additionally, product strength is calculated based on dry material. Unintended results are likely to occur with previously wet products.