In Canada, structural engineers and contractors have a handful of solutions for addressing the risks of expansive soils on concrete structures, from chemical stabilization to mechanical stabilization to, most commonly, structural design in the form of under-foundation void spaces.

Void forms are typically the most cost-effective solution to address the upward pressure of swelling soils because they require shorter installation time, less specialized equipment, and, ultimately, reduce on-site delays. Given the current Canadian systems for weatherproof void products EPS foam voids and StormVoid® —an innovative polypropylene plastic void—the following compares costs, performance, and installation between these two options.

What are EPS Foam Voids?

Also known as void foam, expanded polystyrene (EPS) foam voids are specialized construction materials that shield concrete structures from the upward pressures of expansive soils and frost heave. They may also be deployed to provide lightweight fill solutions in lieu of sand or stone. Historically, EPS foam voids have been widely used in Canada but have gradually fallen out of favor in the U.S. due to environmental concerns and the availability of cost-effective alternatives.

EPS voids are made from expanded polystyrene beads that are heated and fused together, resulting in a structure that is mostly air contained within closed cells. Its compressive strength varies depending on its density and grade, and in Canada, it’s deployed as a weatherproof alternative to paper void forms.

Across the country, there are several EPS void manufacturers and design types. Two of the most widely used formats are a honeycomb-like design and a tabletop design supported with vertical posts.

What is StormVoid?

StormVoid is a recent entrant to the Canadian market. Still, it has been widely used across the U.S. for nearly a decade. It is a non-degradable void form made from moisture-resistant exterior corrugated paper and a waterproof, fluted polypropylene plastic interior.

The StormVoid design is strong enough to withstand particularly wet or inclement site conditions yet developed to flex from the pressures of upward swell from expansive soils or frost heave. After the corrugated paper deteriorates, the soil can expand into the cellular structure without causing damage to the concrete.

Like conventional paper-based void systems, this system maintains a crucial void space between the concrete slab and soil to prevent damage from expansive soils. Unlike paper carton forms, StormVoid can be installed in wet conditions without compromising performance. StormVoid is available in slab, pier, and beam components.

EPS Void and StormVoid: Comparison of Cost, Performance, and Installation

Cost

Carton-based void forms are the most cost-effective option in dry conditions. However, when the weather forecast shifts, contractors must pivot to more weatherproof materials to prevent schedule delays, damaged materials, and subsequent cost overruns.

In Canada, this has traditionally meant a pivot to EPS foam products, as they have long been one of the only waterproof void systems available. However, with alternatives now readily available, contractors have options to weigh the cost and indirect expenses associated with labor and site preparation for EPS foam installation.

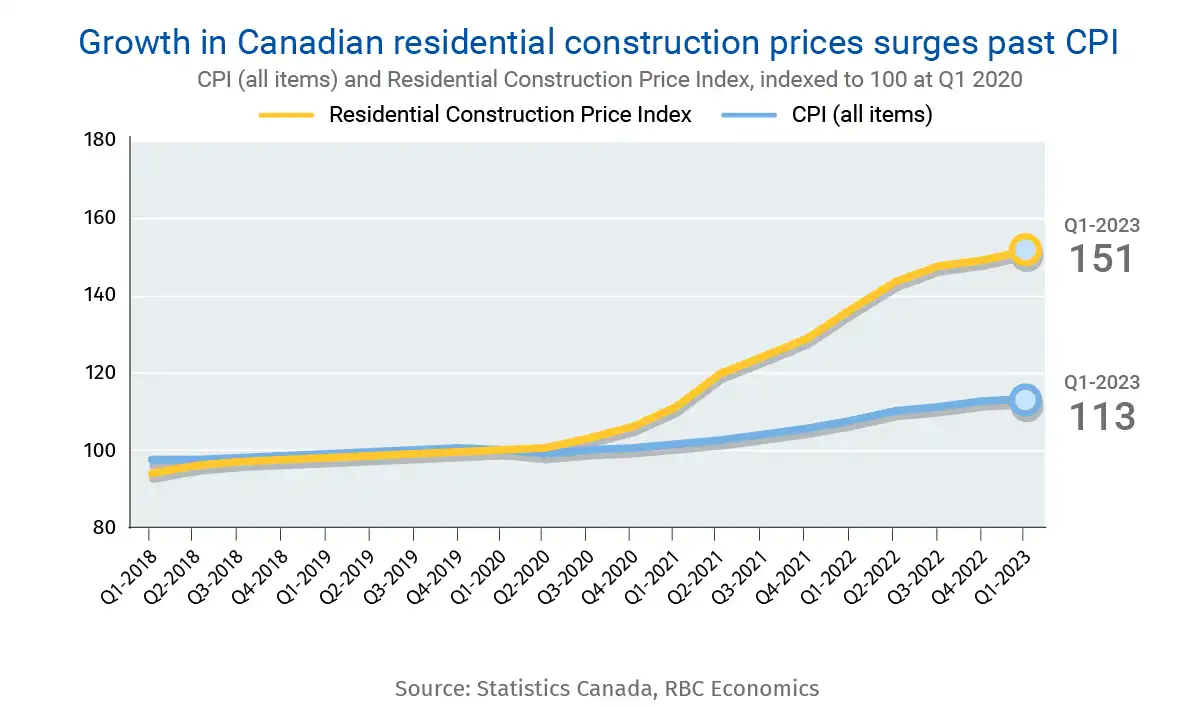

EPS foam voids require more labor to install than prefabricated systems like StormVoid. Many EPS foam products must be cut and fitted on-site, often requiring a minimum of three laborers to position and wire each segment together. These indirect labor costs can escalate rapidly for installations spanning thousands of square feet. As a reminder, labor costs in Canada are soaring, with wages growing in the sector at double the pace of other industries.

When these indirect costs are factored in, StormVoid systems present a more cost-effective alternative to EPS foam. First, StormVoid reduces labor costs by arriving prefabricated and ready to install, eliminating the need for three-person teams to cut and wire segments.

Image credit: Statistics Canada, RBC Economics

Additionally, StormVoid is fabricated to fit the void specified in the geotechnical report. Its interior supports are engineered to withstand concrete placement and bend appropriately under site-specific soil conditions, allowing the soil to expand without creating pressure.

Performance

Void forms, no matter the manufacturer or style, must be strong enough to support the weight of concrete yet weak enough to fail in response to the unique Canadian soil conditions posed by expansive soil and frost heave. What’s more, when wet weather and unfavorable conditions are in the forecast, these products must withstand mud, pooling water, and rain before and after installation.

Ensuring the specified void space is maintained following the concrete pour can be challenging with EPS foam. As mentioned, contractors must over-excavate the site to accommodate the foam, adding to project costs and complexity. Even with careful installation, the potential for compression and uneven settling can make it difficult to guarantee the intended void space will be maintained.

StormVoid has been subjected to 45,000lb compression tests designed to capture force and deflection values of the material’s performance under various load scenarios.

Critically, when the foam is compressed beyond its capacity, it becomes a solid state and offers no more space for soil expansion.

This point is especially challenging for sites installing firmer EPS foam due to exceptionally heavy site specifications. Stronger foam inherently has lower compression capability. Contractors will need to make additional accommodations for this reduced compression capacity.

The StormVoid system is designed to handle designated weights of wet concrete and live loads during the curing period. The outer cardboard layer breaks down with persistent ground moisture over time, leaving only the copolymer plastic grid in place. The internal grid is flexible, with the open structure creating channels for soil to expand within each cell, helping to reduce the powerful upward pressure of expansive soil.

VoidForm, the manufacturer behind StormVoid, runs one of the most robust testing facilities for void products in all of North America. This attention to performance means StormVoid’s components have been subjected to rigorous testing to simulate real-world conditions.

As just one example, StormVoid has been subjected to 45,000lb compression tests designed to capture force and deflection values of the material’s performance under various load scenarios. Considering the first few hours of a concrete pour are the most critical, VoidForms simulates this with a time-based test that mimics the pour, finishing, and final setting stages.

Throughout the testing process, VoidForm determines the safe operating loads for StormVoid and identifies the failure loads, all to protect the structural integrity of your foundation against uplift forces.

Installation

Both EPS voids and StormVoid are lightweight, but certain brands of EPS foam come in impossibly long segments that are brittle and prone to break when shuffled around a job site. This means despite the lightweight nature of the foam, two or more laborers are often required to move individual pieces simply to avoid compromising the components and, most frustratingly, having EPS foam particles blown across the site.

Plus, depending on the manufacturer, most EPS void designs are held in place with wire fasteners to prevent shifting during the concrete pour. These fasteners placed at each honeycomb junction require a specialized skill set and additional labor considerations to ensure each piece’s proper placement and alignment.

VoidForm, the makers of StormVoid, complete take-offs for most projects. That’s because StormVoid is pre-manufactured and site-specific, taking into account slab depth, concrete weight, live loads, and soil conditions. Minimal additional preparation is required, dramatically reducing the resources needed to move components around the site and place them in their final positions. From the crew’s perspective, StormVoid arrives completely assembled and installed easily. No special skills or tools are required.

Trusted by Engineers, StormVoid Keeps Schedules and Budgets on Track

Better on timelines and budgets, StormVoid is a proven alternative to EPS foam to mitigate the risks of expansive soil in Canada. Solving many of the frustrations contractors have preparing brittle and unwieldy pieces of void foam on site, StormVoid is a lightweight and prefabricated system that comes ready to install—no matter how much rain is in the weather forecast.

Get in touch with our Canadian sales team or find a distributor near you to find out about pivoting to StormVoid.